KBE+, Inc. has done extensive development work with gear and chain / sprocket manufacturers to achieve the exacting standard and precision of motion required (very low transmission error) to drive both automotive valve trains and balance shaft cassettes. Our work on balance shaft systems was augmented with our extensive NVH and modal analysis experience. Those combined abilities helped our client develop a cost effective system quickly, which went from prototype to production in record time.

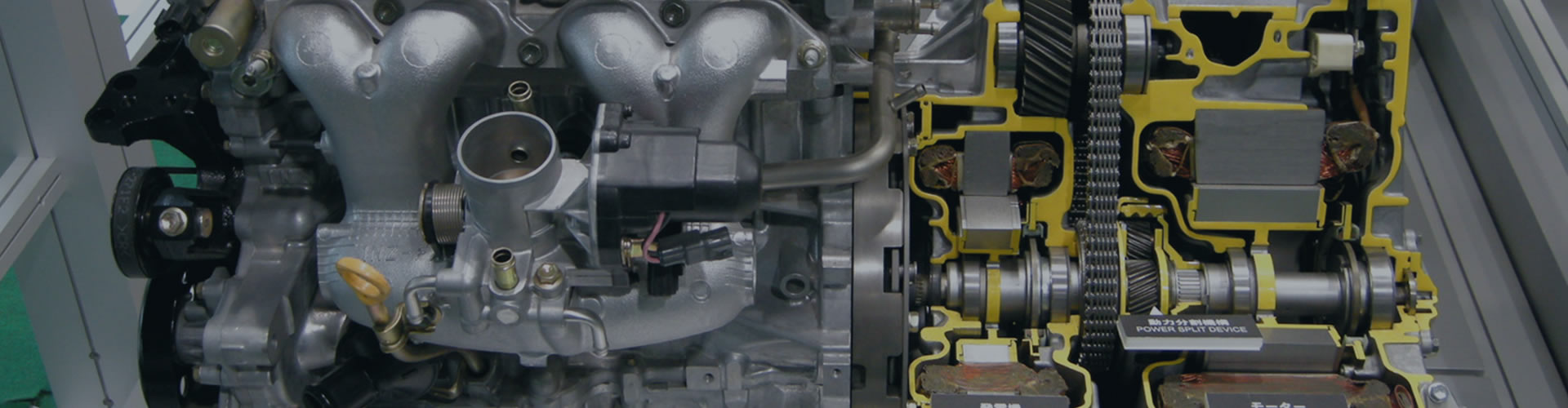

Internal Combustion Engine Design

An Engine Design Success Story

This was a joint project through the McLaren Performance Engine Group of Linamar Corporation, and the Mazda division of Ford Motor Company. KBE+ was engaged to assess quality issues associated with the production of the balance shaft cassette, specifically a transmission error issue. Once successfully resolved, we were then tasked with formulating a strategy to identify the root cause of the problem and define a plan for reducing transmission error to acceptable levels.

Corrective actions suggested by KBE+ completely resolved the transmission error production issues with acceptable cost penalties and minimal changes to their base processes. The techniques used to define the problem and identify the root cause were further leveraged to address other production and quality issues within their engine manufacturing plants.