Product Verification / Validation Test Liaison Services

KBE+, Inc. offers a full range of testing, test support and custom test equipment development services.

Our experience base is derived from over 50 years of direct involvement in testing or test liaison services.

KBE+ provides full support resources and staff to all engineering test projects including full client access

to their test data as it is obtained, on-line review of all completed tests, subjective analysis and objective

photo-documentation.

We also provide every client with 24/7 access to video and audio feeds from their assigned test bay

through a secure WEB site. We have successfully worked with client-specific laboratories to develop new in-house test procedures and test equipment. Finally, we have managed entire test programs for clients on an international basis.

A Verification and Validation Testing Success Story

KBE+ has made a concerted effort to become known for our expertise in unusual gear forms as well as Noise, Vibration and Harshness (NVH) solutions. While it is not common for people to challenge us with ‘interesting’ concepts, it does happen. One particular concept for a gear form was based on the theoretical potential benefit of a tooth form that would allow for rolling (minimal sliding) from the pitch line to the tip of the tooth and conformal contact from near the pitch line to the root of the tooth. Our client presented us with a well developed mathematical model, samples to test, test criteria and conditions along with a rudimentary idea for a test machine.

Our engineers quickly realized that the design was not robust enough for extended duration un-manned testing. So we developed our own concept, designed and detailed it, had all the components fabricated and then assembled the dynamometer ready for test. The system worked flawlessly for several years in our shop, after which the client transferred it to their new facility where it is still used today. As part of this project, we developed a complete test plan, used the techniques of DOE to ensure we were collecting only enough data to ensure statistical significance, as well as test setup, tear-down, inspection, documentation and dynamometer maintenance and calibration procedures.

Another Verification and Validation Testing Success Story

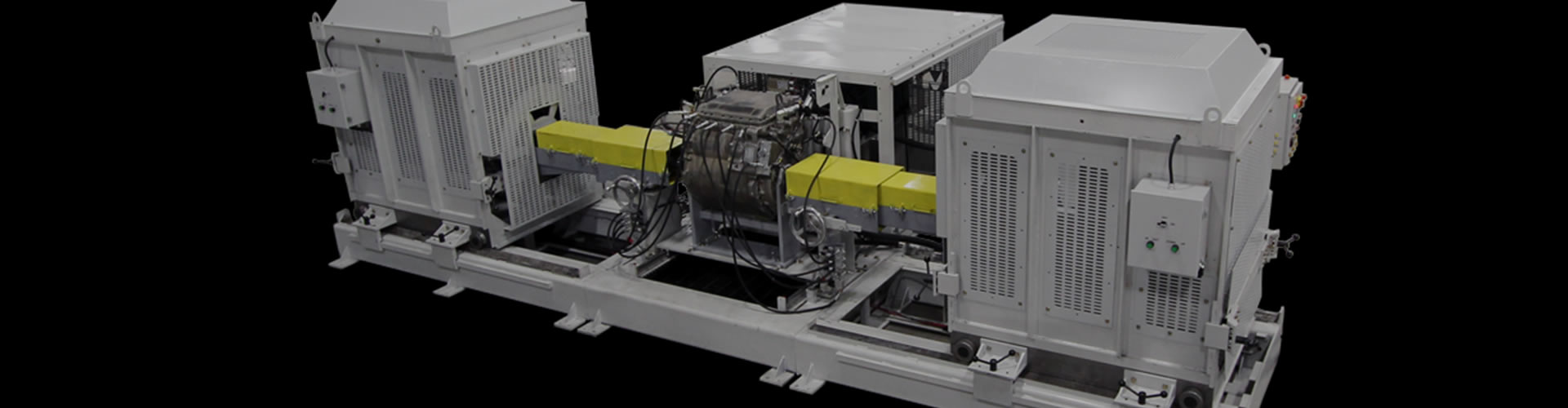

A prospective client approached KBE+ to develop a means to test and validate the operational assumptions of their unique Continuously Variable Planetary (CVP) system. The client’s initial scope of work was for a simple one-horse test stand. However, the power transmission path and the means by which the device worked were unique and as such presented numerable difficulties developing a test stand. Through our collective efforts, we instead developed a fully integrated dynamometer that could be easily and quickly converted from one power transmission configuration to another, with real-time data collection, on-line integration of client control (the client was located across the country from our laboratory facilities) and a base design for building multiple dynamometers for production testing.

The result of our efforts is that the client was able to prove their claims of superior performance, quiet operation and an extended service life over traditional epicyclic based CVPs. They were so successful with their development and marketing efforts that they sold the rights to their technology based largely on the strength and completeness of the test data they had amassed.