We have developed an extensive catalog of suppliers that provide high-quality products and services. This allows us to assist our clients to procure prototypes and/or production parts. We will liaison between our client engineers and procurement personnel to find the right vendor to get the exact part on-time and within budget. This capability also applies to common services within our industry. We work with our partners to provide an extensive array of services including materials, metallurgy, component printing and manufacturing, full first piece dimensional verification, gear accuracy verification, test system and dynamometer design/development and test liaison services.

Prototype Procurement Support Services

A Prototype Support Success Story

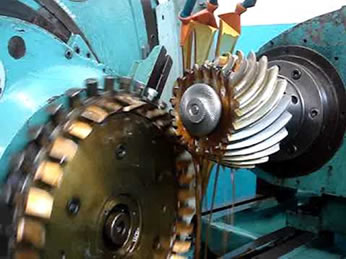

KBE+ engineers were selected to manage the design, design review, manufacturing, commissioning and in-situ testing of the largest gearbox ever built or installed in the amusement park industry. The key aspect of this design was the requirement to interface the gearbox with the electric drive system and to achieve the desired system response specified by the control engineers. The gear mesh stiffness and response frequencies were extremely tightly coupled, which required particularly high gear mesh stiffness. A significant component of the project was identifying a gearbox manufacturer that had the capability to produce the specified design. After extensive research, it was determined that only one gear and gearbox manufacturer in the world could achieve the required design specifications. The drive system was delivered and tested within the project timeline and under budget.

The final ride has been a huge success and met all of the requirements and expectations of the Imagineering Engineers. This is especially noteworthy considering the required gear mesh stiffness is an order of magnitude higher than any other similar sized gear system known in the world at that time.